Malaysia

Breadcrumb navigation

Initiatives in Products and Services

Environmental Requirement

Environmental regulations by Ministry of Energy, Science, Technology, Environment & Climate Change https://www.doe.gov.my/portalv1/tentang-jas/perundangan/akta-kaedah-peraturan-arahan-2/akta

https://www.doe.gov.my/portalv1/tentang-jas/perundangan/akta-kaedah-peraturan-arahan-2/akta

Development of Environmentally Friendly Products

NEC focuses on activities to reduce the environmental impact of products over their entire lifecycle from procurement to use and disposal of products by customers.

In these activities, we have added the perspectives of "Ecology" (including resource recycling, global warming prevention, and environmental consciousness) and "Compliance" to the conventional perspectives of "Quality," "Cost," and "Delivery."

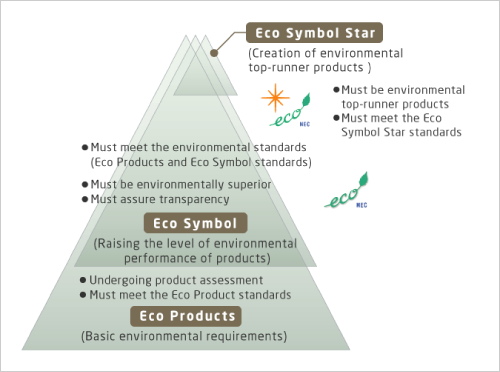

Eco Symbol System

Environmentally friendly products, software, and services that meet NEC's environmental standards are certified and registered in three levels.

Eco Products are products that are confirmed to have met all of the eco product standards, which are NEC's original basic requirements for protecting and preserving the environment, in product assessments conducted by each division during new product development.

Eco Symbol products are Eco Products that meet the Eco Symbol standard that requires products to be even more environmentally advanced and environmentally friendly.

The Eco Symbol Star is assigned to Eco Symbol products, software and services that are regarded as environmental top-runner products, for example conforming to stringent standards such as reducing CO₂ emissions by 50% compared with conventional products.

In fiscal 2019, 10 items, comprising 8 hardware products and 2 software and services were certified as Eco Symbol Star products.

Products conforming to the standard are affixed with the Eco Symbol Star mark in product catalogs, websites, or on the product packaging.

Examples of Eco Symbol Star Registrations in Fiscal 2020

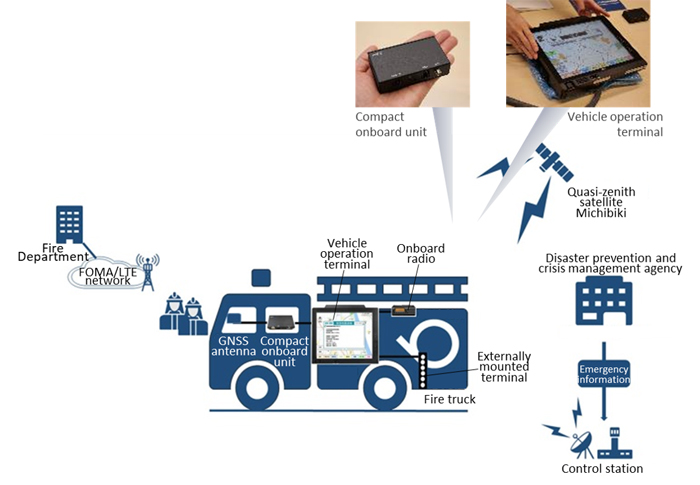

Vehicle Interface Box (E1834-01)

A compact in-vehicle device compatible with the firefighting industry's first "Disaster and Crisis Management Report Service" offered by Michibiki (Quasi-Zenith Satellite System) for transmitting disaster-related and crisis management information.

The capabilities of GPS, sensors, and in-vehicle signals combine to provide precise navigation information to enable fire trucks and ambulances to rapidly arrive at the disaster scene when an emergency call is received. In addition, its compact size (size is significantly smaller and weight significantly less than that of existing devices) has resulted in a 95% reduction in environmental burden per unit.

Highly accurate vehicle location information can be acquired from Michibiki to provide optimal routes to disaster locations, enabling faster response times, which also helps to reduce CO₂. Its compatibility with the firefighting industry's first disaster and crisis management report service helps to advance firefighting procedures and to maintain high levels of safety.

SX-Aurora TSUBASA (VE1E Card/Water-cooled Model)

The Vector Engine (VE1E care/water-cooled model executes complicated applications for supercomputers. It has a higher memory bandwidth than previous models for improved real performance and cooling components optimized for each mounting position, which allows double the previous mounting density. Together these features enable a 3% improvement in annual CO₂ emissions compared with previous models, which had already achieved CO₂ emissions reductions of 50% or more.

Batch-type System Development Platform "System Director Enterprise for Batch"

This tool can be used in batch-type system development projects to automatically generate code and design documents that have conventionally been written manually.

In particular, since batch-type systems involve significant typical processing, they include a large number of source lines that can be generated automatically. Furthermore, since the result has a consistent character, it also has improved maintainability.

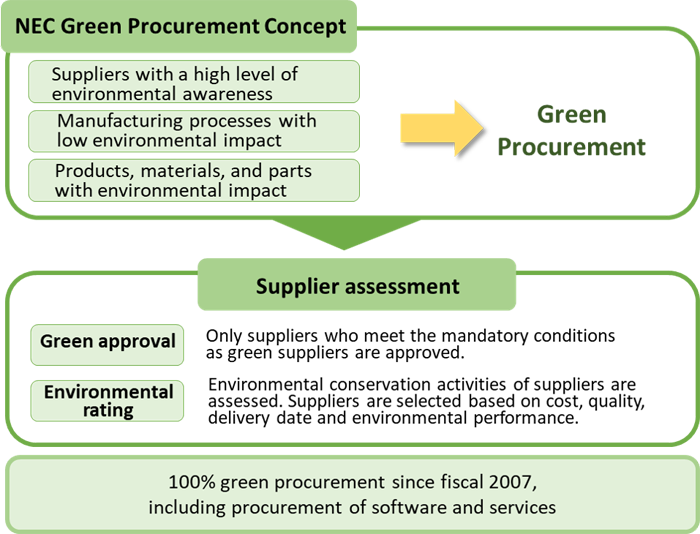

Green Procurement

Green Procurement Policies

NEC is making a Company-wide effort to promote "green procurement," which involves prioritizing procurement of items that are environmentally friendly under the concept of "environmentally conscious suppliers, low-impact manufacturing processes, and low-impact parts and materials." Our objectives are to expand the green product market towards building a recycling-oriented society, promote the development of recycling-oriented products for such a society, and to raise awareness among designers and developers.

As part of our environmental target to convert all NEC products into environmentally sound items, we began a "Green Approval" municipalities system in fiscal 2003, and since fiscal 2007 we have achieved a 100% procurement rate from green approved suppliers.

Furthermore, we adopted an environmental rating system to evaluate and rate suppliers' environmental preservation activities, and we give priority to green approved suppliers who are most proactive in their environmentally sound activities.

Our supplier evaluation applies not only to materials and parts suppliers, but also to suppliers of intangible products such as software and services.

Green Procurement Guidelines

To promote green procurement, NEC has established Green Procurement Guidelines. These guidelines present "essential requirements," the minimum requirements that we ask suppliers to observe for green procurement, and "requests," which we ask suppliers to consider incorporating into their environmental activities.

With regard to the "essential requirements" for suppliers, purchased products that are incorporated in or shipped together with NEC's products must satisfy requirements (1) to (4), while other purchased products such as software, services, pharmaceuticals, gases, and supplies must satisfy requirement (1).

Essential Requirements

- (1)Create an environmental management system within the factory where products are developed and manufactured, and the offices and so forth from which they are marketed.

- (2)Do not use banned substances in the manufacturing process.

- (3)Respond to the survey of chemical substances contained in the procurement product.

- (4)Products must not contain banned substances or conditionally banned substances.

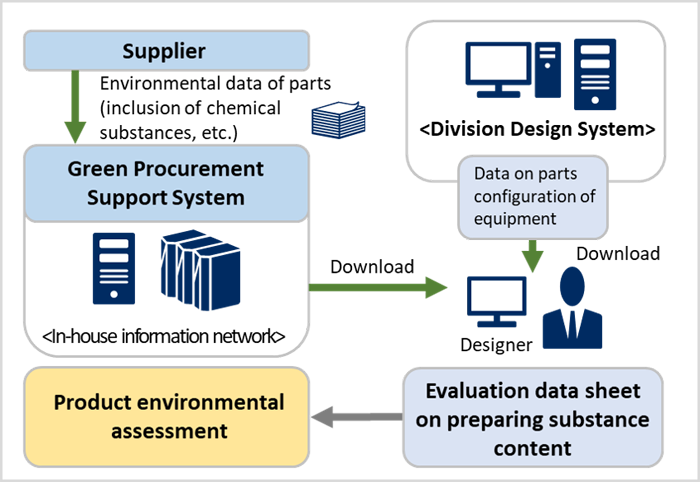

Green Procurement Support System

Since 1997, NEC has investigated the status of environmental pollutants contained in items purchased from suppliers and managed them by registering them in a Green Procurement Support System (CHEMSIS). Using this database, we ensure that all NEC products comply appropriately to regulations on chemical substances in Japan and overseas, and develop products that have a lower environmental burden.

Compliance with Regulations on Chemical Substances Contained in Products

NEC complies with global regulations on chemical substances contained in products, such as the overseas RoHS directive and REACH regulations. To ensure that we comply appropriately with these laws and regulations, NEC is promoting the exchange of information on chemical content through the supply chain and enhancement in the internal structure of information management.

The rational approach to the exchange of information on chemical content is not to introduce individual rules but to employ the common use of chemSHERPA, a scheme for the sharing and exchange of information on the chemicals contained in new products in supply chains compliant with international standard IEC 62474. Such an approach contributes to lessened workloads for both the side providing the information and the side receiving the information. NEC has built a compliance structure using chemSHERPA-CI*1 and chemSHERPA-AI,*2 which are operated by JAMP.*3

- ※1Sheet for entering the information on the chemical substances that are contained in the material or prescription that are to comply with the laws and regulations.

- ※2Sheet for entering information on the chemical substances that are contained in the formed articles that are to comply with the laws and regulations.

- ※3JAMP: Joint Article Management Promotion – consortium

Complying with the EU Restriction of Hazardous Substances (RoHS) Directive

The EU RoHS Directive bans, in principle, the inclusion of 10 substances, including lead, mercury, and cadmium, in electrical and electronic products. NEC requests its suppliers to comply with the EU RoHS Directive in products that they supply, and conducts surveys to determine whether purchased parts and materials contain any of the banned substances. These efforts ensure that NEC branded products comply with the EU RoHS Directive, in principle.

<Progress of Replacement>

NEC had already prohibited the inclusion of four phthalic acid compounds in purchased products one year before the enforcement of a law that banned them in July 2019, and has made progress in replacing them.

Lead solder is being replaced with lead-free solder.

Pigments and paints have been changed to materials that do not contain lead, cadmium or hexavalent chromium.

Procurement of parts and materials containing PBDE and PBB has been banned since 1997, so other flame retardants are used.

Hexavalent chromium plating in the treatment of steel sheets and plates is being substituted by trivalent chromium plating, organic film, nickel plating and stainless steel.

<Management of Exceptions>

The EU RoHS Directive includes exceptions where the inclusion of prohibited substances is permitted under certain conditions. These can be used within a legally allowed period, but are required to be definitely replaced at an appropriate time.

NEC manages risks using an internal system called CHEMSIS, which centrally manages information on chemical substances contained in purchased products collected with chemSHERPA-AI, then automatically determines whether contained substances exceed threshold values and the time limit on exemptions. At the same time, we ask suppliers to comply with the end of exemption periods six months in advance.

<Confirmation by Analysis>

For purchased products that are deemed to be high risk, we obtain analysis data from the supplier and when necessary conduct our own individual analysis to confirm that prohibited substances are not contained in the products. The NEC Group has introduced fluorescent X-ray analysis systems in its production plants to create a system for confirming that certain prohibited substances, such as lead, cadmium, mercury, and hexavalent chromium, are not contained in the products.

<Vietnam RoHS>

NEC is complying with CIRCULAR, No.30/2011/TT-BCT (Hanoi, August 10 2011), temporarily regulating the permitted limits for certain hazardous substances in electronic and electric products.

Complying with the EU REACH Regulations

The EU REACHRegulations identify restricted substances that may not be included in products and Substances of Very High Concern (SVHCs), that may be included but require provision of information to product recipients if they exceed a certain threshold value.

NEC uses chemSHERPA-AI to request provision of the above chemical substance information from its suppliers and manages the response information obtained centrally on its internal system, CHEMSIS, to control the presence of restricted substances and SVHCs in excess of threshold values.

Response to Other Global Regulations

In addition to the EU RoHS Director and EU REACH Regulations, NEC's business divisions all work together with local subsidiaries and relevant industry organizations in Japan and overseas to comply with a globally expanding body of regulations on chemical substances contained in products.

Supplier Code of Conduct

Supplier Code of Conduct

Larger view

Larger view